What Is Industry 4.0

What is Industry 4.0? A Comprehensive Interpretation of the Fourth Industrial Revolution

Industry 4.0: The Ultimate Guide to the New Era of Smart Manufacturing | Comprehensive Analysis of Key Technologies, Application Scenarios, and Future Trends

Industry 4.0 is a high-tech strategic initiative proposed by the German government in 2011, recognized as the core driver of the Fourth Industrial Revolution. This concept represents the digital, intelligent, and networked transformation of manufacturing. Through the deep integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data, it aims to build intelligent production systems capable of autonomous decision-making. Industry 4.0 is not merely a technological innovation but a reshaping of the entire manufacturing value chain, fundamentally transforming traditional production methods and business models.

Core Features and Key Technologies of Industry 4.0

# 1. Interconnectivity

Through Industrial Internet of Things (IIoT) technology, comprehensive connectivity is achieved among devices, sensors, control systems, and personnel. Smart sensors collect production data in real time, while cloud platforms process and analyze it centrally, forming a complete production data chain.

# 2. Information Transparency

Digital Twin technology creates precise virtual replicas of physical entities. Managers can monitor equipment status, production progress, and quality metrics in real time, enabling end-to-end visual management.

# 3. Decentralized Decision-Making

AI algorithms enable autonomous decision-making based on real-time data, including production scheduling, quality control, and equipment maintenance. The system can automatically optimize production parameters to improve operational efficiency.

# 4. Technical Assistance

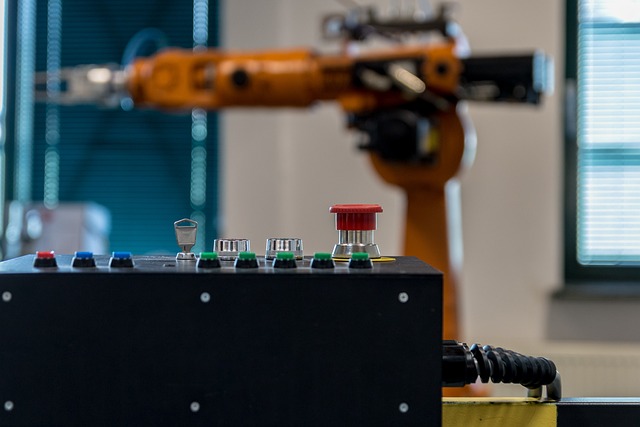

Augmented Reality (AR) and Virtual Reality (VR) technologies provide operational guidance and technical support to workers. Collaborative robots (Cobots) work alongside humans, enhancing production safety and efficiency.

Key Technology Stack of Industry 4.0

| Technology Area | Core Technologies | Application Scenarios |

|—————————————–|———————————————————–|——–———-—————————————-|

| Connectivity Technologies | 5G, IIoT, Time-Sensitive Networking (TSN) | Device Interconnection, Real-Time Control |

| Computing Technologies | Edge Computing, Cloud Computing, Fog Computing | Data Processing, Storage, and Analysis|

| Intelligent Technologies | AI, Machine Learning, Deep Learning | Predictive Maintenance, Quality Inspection |

| Visualization Technologies | Digital Twin, AR/VR, Data Visualization | Equipment Monitoring, Operational Guidance |

| Manufacturing Technologies | Additive Manufacturing, Robotic Process Automation (RPA) | Flexible Production, Customized Manufacturing |

Typical Application Scenarios of Industry 4.0

# 1. Smart Factory

By deploying sensors and IoT devices, real-time monitoring of production equipment and predictive maintenance are achieved. The production system can automatically adjust parameters to adapt to different production needs. For example, Siemens’ Amberg Electronics Factory improved production efficiency by 75% and achieved a product quality rate of over 99% through Industry 4.0 transformation.

# 2. Personalized Customized Production

Based on Industry 4.0 technologies, enterprises can achieve large-scale personalized customization. Customers can design products independently through online platforms, and the production system automatically generates production process routes. For instance, Haier’s COSMOPlat platform allows users to customize refrigerators, reducing the production cycle by more than 50%.

# 3. Supply Chain Optimization

Blockchain technology combined with IoT enables end-to-end traceability in supply chains. Smart contracts automatically execute business processes such as procurement and payments, improving supply chain transparency and management efficiency.

# 4. Predictive Maintenance

By analyzing equipment operational data, AI systems can predict potential failures in advance and automatically schedule maintenance plans. Research shows that predictive maintenance can reduce equipment downtime by 30-50% and lower maintenance costs by 10-40%.

Step-by-Step Guide to Implementing Industry 4.0

1. Current State Assessment and Planning

– Conduct a digital maturity assessment.

– Develop a clear digital transformation roadmap.

– Define key performance indicators (KPIs).

2. Infrastructure Construction

– Deploy an IIoT platform.

– Build a 5G private network or industrial WiFi.

– Implement cloud and edge computing facilities.

3. System Integration and Data Management

– Integrate ERP, MES, PLM, and other systems.

– Establish a unified data management platform.

– Implement data governance and security strategies.

4. Pilot Projects and Scaling

– Select key production lines for pilot projects.

– Validate the feasibility of technical solutions.

– Gradually scale to full factory implementation.

Benefits and Value of Industry 4.0

1. Improved Operational Efficiency

– Production efficiency increased by 20-30%.

– Overall Equipment Effectiveness (OEE) improved by 10-20%.

– Production cycle shortened by 30-50%.

2. Quality Enhancement

– Product defect rate reduced by 10-30%.

– Quality inspection costs lowered by 20-40%.

– Significant improvement in customer satisfaction.

3. Cost Optimization

– Inventory costs reduced by 20-30%.

– Energy consumption decreased by 10-20%.

– Labor costs optimized by 15-25%.

Challenges and Countermeasures for Implementing Industry 4.0

# Key Challenges:

1. Data security and cybersecurity risks.

2. Difficulty in retrofitting traditional equipment and system integration.

3. Shortage of specialized technical talent.

4. High initial investment costs.

# Strategies:

– Adopt a layered security protection system.

– Develop a phased implementation plan.

– Enhance employees’ digital skills through training.

– Seek government subsidies and partner support.

Future Trends of Industry 4.0

1. Deep Integration of Artificial Intelligence

Machine learning algorithms will play a greater role in quality control and production optimization, enabling higher levels of automated decision-making.

2. Sustainable Development

Industry 4.0 technologies will help enterprises achieve green manufacturing by optimizing energy usage and reducing waste, thereby minimizing environmental impact.

3. Servitization Transformation

Manufacturing enterprises will transition from product providers to service solution providers, creating new revenue streams through data services.

4. Ecosystem Collaboration

Enterprises will achieve cross-enterprise collaboration through industrial internet platforms, building more flexible and efficient industrial ecosystems.

Conclusion

Industry 4.0 is reshaping the global manufacturing competitive landscape, offering unprecedented development opportunities for enterprises. By implementing Industry 4.0, enterprises can not only enhance operational efficiency and product quality but also innovate business models and strengthen market competitiveness. It is crucial to adopt a systematic implementation approach tailored to the enterprise’s actual situation.

For manufacturing enterprises, now is the best time to embrace Industry 4.0. By progressively advancing digital transformation, enterprises can secure a favorable position in the new industrial revolution and achieve sustainable development.