Titanium Alloys: Properties, Applications, and Key Advantages in Modern Industries

Introduction to Titanium and Alloys

Titanium is a polymorphic metal. Below 882°C, it is in the α-phase, with a close-packed hexagonal atomic structure. From 882°C up to its melting point, it is in the β-phase, with a body-centered cubic lattice. Industrially pure titanium exhibits the α-phase in its metallographic structure. If fully annealed, it forms a monophasic, equiaxed lattice of essentially equal size. Due to impurities, a small amount of β-phase is also present in industrially pure titanium, primarily distributed along grain boundaries.

Titanium alloys are advanced metallic materials renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These properties make them indispensable in aerospace, medical, automotive, and industrial sectors. As demand for high-performance materials grows, understanding titanium alloys’ characteristics and applications becomes critical for engineers, designers, and industry stakeholders.

Key Properties of Titanium Alloys

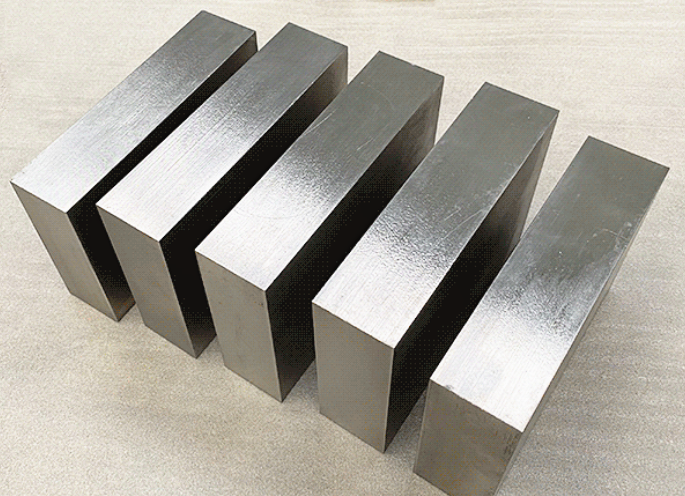

1. High Strength-to-Weight Ratio

Titanium alloys offer tensile strength comparable to steel but with 45% lower density, making them ideal for weight-sensitive applications like aerospace and automotive components.

2. Exceptional Corrosion Resistance

These alloys form a protective oxide layer, enabling resistance to harsh environments, including seawater, chemicals, and extreme temperatures. This property is vital for marine engineering and chemical processing equipment.

3. Biocompatibility

Titanium’s non-toxic nature and compatibility with human tissue make it the top choice for medical implants, such as joint replacements and dental prosthetics.

4. High-Temperature Performance

Alloys like Ti-6Al-4V retain strength at temperatures up to 600°C, suitable for jet engines and gas turbines.

5. Fatigue Resistance

Titanium alloys withstand cyclic loading, extending the lifespan of critical components in aerospace and automotive systems.

Major Titanium Alloy Types and Compositions

|——————————————————————————————————-|

| Alloy Type | Key Components | Primary Applications |

|————————|———————————————|———————————|

| Ti-6Al-4V | 6% Aluminum, 4% Vanadium | Aerospace, medical implants |

| Ti-6Al-2Sn-4Zr-2Mo | Aluminum, Tin, Zirconium, Molybdenum | High-temperature aerospace parts |

| Ti-3Al-2.5V | 3% Aluminum, 2.5% Vanadium | Hydraulic systems, bicycle frames |

| Ti-5Al-2.5Sn | 5% Aluminum, 2.5% Tin | Cryogenic applications, spacecraft |

|——————————————————————————————————–|

Applications of Titanium Alloys

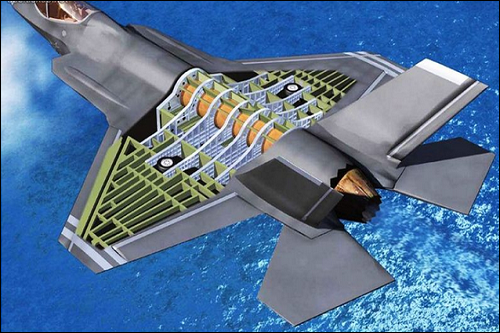

1. Aerospace Industry

Titanium alloys are used in aircraft engines, landing gear, and structural components due to their lightweight and high-temperature resilience. The Boeing 787 and Airbus A350 utilize titanium alloys for up to 15% of their airframe weight.

2. Medical Devices

From orthopedic implants to surgical instruments, titanium’s biocompatibility ensures minimal immune response and long-term durability.

3. Automotive Sector

High-performance vehicles use titanium alloys in exhaust systems, valve springs, and connecting rods to reduce weight and enhance fuel efficiency.

4. Marine and Offshore Engineering

Subsea pipelines, propeller shafts, and offshore rig components leverage titanium’s resistance to seawater corrosion.

5. Consumer Goods

Premium sports equipment (e.g., golf clubs, bicycle frames) and electronics benefit from titanium’s strength and lightweight properties.

Future Trends and Innovations

1. Additive Manufacturing

3D-printed titanium components are revolutionizing prototyping and custom part production, especially in aerospace and healthcare.

2. Sustainable Production

Efforts to reduce energy-intensive extraction processes (e.g., Kroll process) are driving research into electrochemical methods.

3. Hybrid Alloys

New composites, such as titanium matrix composites (TMCs), promise enhanced strength and thermal stability for next-generation applications.

—

Conclusion

Titanium alloys represent the pinnacle of modern materials engineering, combining unparalleled strength, corrosion resistance, and versatility. From saving lives with medical implants to enabling breakthroughs in aerospace technology, these alloys continue to push the boundaries of innovation. As research advances and production costs decrease, titanium alloys will play an even greater role in shaping future technologies.

Explore titanium alloys for your industry to leverage their unique properties and stay ahead in the competitive landscape of advanced materials.