How AI is Revolutionizing Manufacturing: Applications, Benefits, and Future Trends

Artificial Intelligence (AI) is transforming manufacturing into a smarter, more efficient, and highly adaptive industry. From optimizing production lines to enabling predictive maintenance, AI-powered solutions are reshaping how products are designed, produced, and delivered. Here’s a comprehensive look at how AI is applied in manufacturing and what it means for the future.

—

1. Predictive Maintenance

AI analyzes real-time data from sensors embedded in machinery to predict equipment failures before they occur. By monitoring variables like temperature, vibration, and noise, AI algorithms identify patterns indicating potential breakdowns. This reduces unplanned downtime, extends machinery lifespan, and cuts maintenance costs.

Example: Siemens uses AI-driven predictive maintenance to monitor industrial equipment, slashing downtime by up to 50%.

—

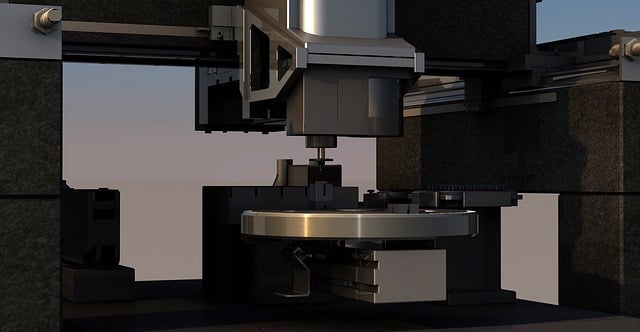

2. Quality Control and Defect Detection

Computer vision systems powered by AI inspect products for defects with unparalleled accuracy. These systems analyze images or videos of items on production lines to identify imperfections (e.g., cracks, discolorations, or misalignments) faster and more reliably than human inspectors.

Example: BMW uses AI-based visual inspection systems to detect minute flaws in car paint and components.

—

3. Supply Chain Optimization

AI optimizes supply chains by forecasting demand, managing inventory, and identifying logistical bottlenecks. Machine learning algorithms analyze historical data, market trends, and external factors (e.g., weather, geopolitical events) to improve procurement, production scheduling, and distribution.

Example: Coca-Cola uses AI to predict demand fluctuations and optimize inventory levels across global networks.

—

4. Generative Design

AI-driven generative design software explores thousands of design permutations based on input parameters (e.g., weight, material, cost). It proposes optimized designs that meet performance requirements while reducing material waste and production costs.

Example: Airbus used generative design to create lightweight, robust cabin partitions, reducing weight by 45%.

—

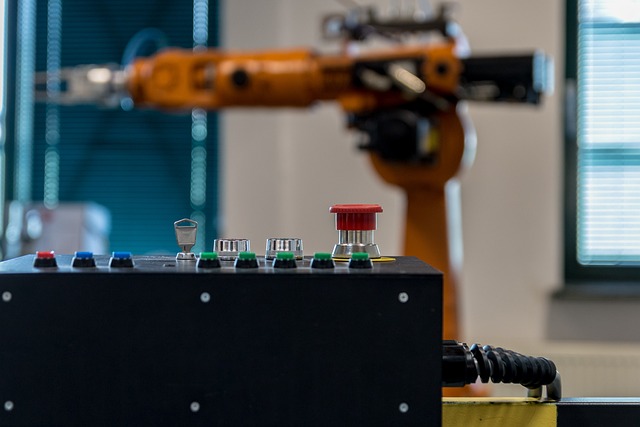

5. Robotics and Automation

AI enhances industrial robots with capabilities like adaptive learning, computer vision, and collaborative functionality. These robots can perform complex tasks (e.g., assembly, welding, packaging) alongside humans, improving efficiency and safety.

Example: Fanuc’s AI-powered robots learn from human demonstrations to refine their actions over time.

—

6. Energy Efficiency

AI monitors and optimizes energy consumption in factories by analyzing data from IoT sensors. It identifies energy-intensive processes and suggests adjustments to reduce waste, lower costs, and support sustainability goals.

Example: Google uses DeepMind’s AI to reduce energy consumption in its data centers by 40%.

—

7. Production Line Optimization

AI algorithms analyze production data in real-time to identify inefficiencies, balance workloads, and streamline operations. This minimizes bottlenecks, improves throughput, and reduces waste.

Example: Foxconn uses AI to optimize assembly lines for smartphones, boosting productivity by 30%.

—

8. Human-Robot Collaboration

AI enables cobots (collaborative robots) to work safely with humans. These robots adapt to dynamic environments, assist with repetitive tasks, and enhance precision without replacing human workers.

Example: Amazon’s warehouses use cobots to assist workers in picking and packing items, increasing efficiency by 50%.

—

9. Customization and Mass Personalization

AI facilitates large-scale customization by adapting production processes to individual customer preferences. From tailored apparel to personalized electronics, AI ensures flexible manufacturing without sacrificing efficiency.

Example: Adidas uses AI-driven factories to produce customized sneakers based on customer specifications.

—

10. Workforce Training and Safety

AI-powered VR/AR simulations train workers on complex machinery and safety protocols. Computer vision systems also monitor workplaces to detect unsafe behaviors (e.g., not wearing protective gear) and prevent accidents.

Example: Boeing uses AR glasses powered by AI to guide technicians through complex aircraft assembly processes.

—

Challenges and Considerations

While AI offers immense benefits, manufacturers must address:

– Data Security: Protecting sensitive production data from cyber threats.

– Integration Costs: High initial investment for AI infrastructure.

– Workforce Adaptation: Reskilling employees to work with AI systems.

– Ethical Concerns: Ensuring transparency and fairness in AI decisions.

—

The Future of AI in Manufacturing

1. Autonomous Factories: Fully automated plants with minimal human intervention.

2. AI-Driven Sustainability: Reducing carbon footprints through optimized resource use.

3. Hyper-Personalization: Producing unique products at scale.

4. AI-Embedded IoT: Smarter sensors and devices for real-time decision-making.

—

Conclusion

AI is not just an upgrade—it’s a paradigm shift for manufacturing. By embracing AI, companies can achieve unprecedented levels of efficiency, quality, and flexibility. From predictive maintenance to generative design, the applications are vast and transformative. As AI technology evolves, manufacturers who adopt it early will lead the industry into a smarter, more innovative future.