From Craftsmanship to Intelligent Manufacturing: An Evolutionary History of Human Processing and Manufacturing

The history of human civilization is, in a sense, an evolutionary history of processing and manufacturing technology. From relying on hands and simple tools to harnessing steam, electricity, and even computational power, every leap in manufacturing methods has profoundly reshaped social productivity and human lifestyles. This magnificent history, driven primarily by three industrial revolutions, has completed an astonishing transformation from “manufacturing” to “intelligent manufacturing.”

1. The Handicraft Era: The Origin of Manufacturing and the Glory of Artisans

Before the Industrial Revolution, handicraft was the absolute norm for a long time. The characteristics of this period were:

- Production Units: Household workshops or small manual workshops. Artisans (such as blacksmiths, carpenters, weavers) possessed comprehensive skills and independently completed all or most processes of a product.

- Power Sources: Relied purely on human labor and animal power, occasionally using simple water or wind power (e.g., watermills).

- Tools and Skills: Simple manual tools (e.g., hammers, chisels, shuttles, needles) were used. The quality and efficiency of products depended entirely on the artisan’s skill, experience, and physical strength.

- Product Characteristics: Products were unique and artistic, but output was very low, costs were high, and specifications were difficult to standardize.

Although this model could create exquisite artworks, it could not meet the growing population and market demand, becoming a bottleneck in productivity development. The call for change grew increasingly urgent.

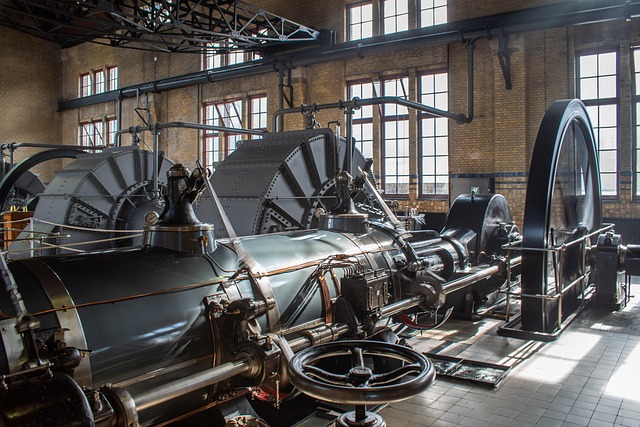

2. The First Industrial Revolution (circa 1760s–1840s): Steam Power and the Dawn of Mechanized Production

The First Industrial Revolution, which began in Britain in the mid-to-late 18th century, completely broke the limitations of manual production and ushered humanity into the machine age.

- Core Driver: The Steam Engine

James Watt’s improved steam engine was the heart of this revolution. It provided a stable and powerful power source unrestricted by geography or climate. Factories no longer needed to be built by rivers but could be concentrated in cities, constructed around massive steam engines. - Invention of Key Machines:

- Textile Industry: John Kay’s flying shuttle, James Hargreaves’ spinning jenny, Richard Arkwright’s water frame, and Edmund Cartwright’s power loom. These inventions mechanized textile production, the core industry, separating it from household handicrafts and achieving exponential efficiency growth.

- Metalworking: Henry Maudslay invented the modern lathe, hailed as the “mother of machines.” It enabled precise and batch production of metal parts, achieving standardization and interchangeability, laying the foundation for manufacturing more complex machines.

- Transformation of Production Models:

- The factory system was established. Workers gathered in factories to operate machines driven by a unified power source, performing highly specialized tasks. Artisans became operators, and the manufacturing process shifted from “human-centered” to “machine-centered.”

- Production power shifted from human and natural forces to steam power.

Outcome: Unprecedented improvements in production efficiency, the rise of industrial cities, andgreat prosperity of commodity economy, but also brought about suffering for the working class and new social contradictions.

3. The Second Industrial Revolution (circa 1870s–1914): Electricity, Assembly Lines, and Mass Production

From the late 19th century to the early 20th century, the Second Industrial Revolution pushed manufacturing to new heights, with its core being mass production.

- Core Drivers: Electricity and the Internal Combustion Engine

- The application of electricity was revolutionary. Electric motors replaced bulky steam engines, providing independent, flexible, and clean power for each machine. Factory layouts became more flexible, and the establishment of power grids enabled long-distance energy transmission.

- The invention of the internal combustion engine provided power for transportation and mobile machinery, further expanding market reach.

- The Pinnacle of Production Models: The Assembly Line

- The most iconic example was Henry Ford‘s application of the moving assembly line in automobile manufacturing. It broke down the manufacturing process of a product (e.g., the Model T) into hundreds of simple, standardized steps, with each worker responsible for only one task.

- This drastically reduced production costs and dependence on worker skills, achieving unprecedented scale and efficiency, making products like automobiles accessible to ordinary families.

- New Materials and Industries:

- Large-scale steel production (e.g., the Bessemer process) provided a strong framework for machines, railways, and buildings.

- The rise of the petrochemical industry provided fuels and new materials (e.g., plastics).

- Telegraphs and telephones improved communication, coordinating more complex production and distribution networks.

Outcome: Scale and standardization became the golden rules of manufacturing, modern corporate giants emerged, and consumer society began to take shape.

4. The Third Industrial Revolution (circa 1950s–Present): Automation, Computers, and Digital Manufacturing

After World War II, the Third Industrial Revolution (also known as the Digital Revolution), marked by computers and information technology, is pushing manufacturing from “automation” to “intelligence.”

- Core Drivers: Computers and the Internet

- The emergence of programmable logic controllers (PLCs) and industrial robots enabled automation of production lines, allowing uninterrupted 24/7 execution of repetitive, heavy, or precise tasks.

- The application of computers brought computer-aided design (CAD) and computer-aided manufacturing (CAM). Products could be designed and simulated in virtual space before being precisely physically processed through equipment like CNC machines, significantly shortening R&D cycles.

- Transformation of Production Models:

- Flexible Manufacturing Systems (FMS) emerged, allowing production lines to quickly switch between manufacturing different product models, breaking the rigidity of Ford-style assembly lines that could only produce a single product.

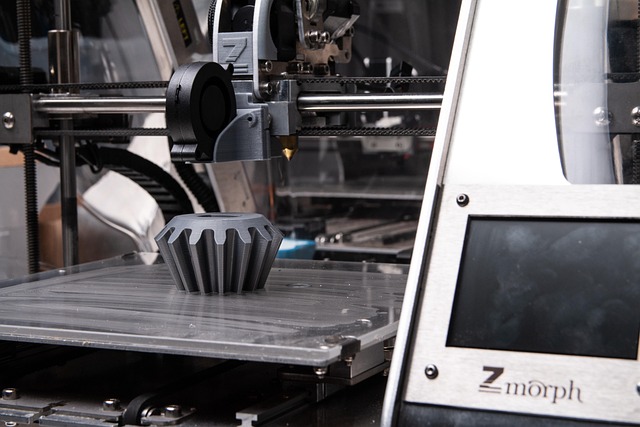

- In recent years, the maturation of additive manufacturing, i.e., 3D printing technology, marks a paradigm shift from “subtractive manufacturing” to “additive manufacturing.” It can create complex structures impossible with traditional methods, making it ideal for small-batch, customized production.

- Global supply chains formed under the coordination of the internet, turning the world into a giant “factory.”

- New Trends: Industry 4.0 and Smart Manufacturing

Currently, we are in the deepening stage of the Third Industrial Revolution, often referred to as “Industry 4.0.” Its core is cyber-physical systems (CPS), which use Internet of Things (IoT), big data, and artificial intelligence (AI) technologies to enable real-time communication and collaboration between machines, products, and people. Smart factories can self-predict, self-adjust, and self-optimize, achieving mass customization.

Outcome: Manufacturing is becoming increasingly digital, networked, and intelligent, meeting personalized demands, but also posing new challenges to labor skills.

Conclusion

From the skilled hands of artisans to roaring steam engines, from efficient assembly lines to silent intelligent robots, the history of processing and manufacturing is an epic of human wisdom liberating physical labor and expanding capabilities. The three industrial revolutions were not only changes in power and tools but also upheavals in entire production paradigms, economic structures, and social forms. Today, we stand on the threshold of the era of smart manufacturing. This history tells us that the only constant is change itself, and the pace of human innovation never stops.