Five Most Common Manufacturing Processes in the World

From the cars we drive and the smartphones we use to the skyscrapers we live in, everything in modern civilization is built upon precision manufacturing. Behind it all are several mainstream manufacturing processes that have evolved over thousands of years and remain core to production today. These are: casting, forging, stamping, welding, and CNC machining. This article will provide an in-depth look at the principles, characteristics, and applications of these five processes.

Basic Principles and Features

#1. Casting – The “Art of Solidification” That Gives Form

Casting is one of the oldest metal-forming processes mastered by humanity. Its principle can be summarized as: pouring liquid material into a pre-made mold cavity, allowing it to cool and solidify, and obtaining a part (casting) of the desired shape.

Basic Principle: Similar to using a mold to make ice cubes or chocolates. Molten metal (such as iron, aluminum, copper, zinc, etc.) fills the mold through gravity, pressure, or centrifugal force.

Key Steps:

1. Mold Making: Create a cavity (mold) based on the part drawing, typically using sand (sand casting), metal (die casting), or investment patterns (lost-wax casting).

2. Pouring: Pour the molten metal into the gating system, allowing it to fill the cavity.

3. Cooling and Shakeout: Wait for the metal to solidify inside the mold, then break the mold (like sand mold) or open the mold (like metal mold) to remove the casting.

4. Post-Processing: Remove gates, risers, and burrs from the casting, and perform necessary heat treatment to improve properties.

Main Advantages:

- Unmatched Complexity: Can produce parts with extremely complex shapes and intricate internal cavities, such as engine blocks and artworks.

- Wide Material Range: Almost any metal that can be melted can be used for casting.

- Cost-Effective: Very suitable for mass production, with low cost per unit.

Limitations:

- Castings are prone to internal defects like porosity and shrinkage.

- Mechanical properties are generally inferior to forgings, with lower strength and toughness.

- Relatively poor surface finish and dimensional accuracy.

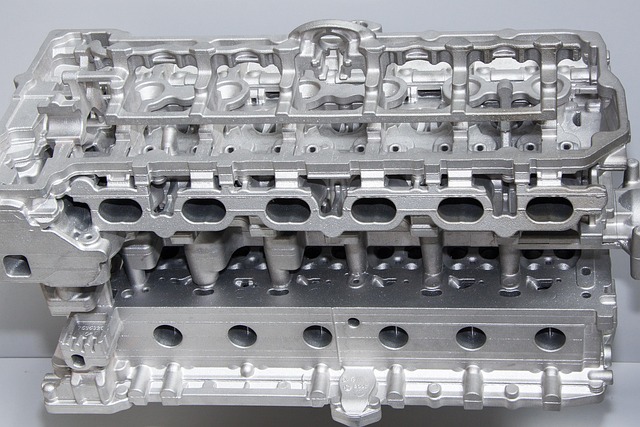

- Typical Applications: Automotive engine blocks/cylinder heads, machine tool beds, pipe fittings, large statues, aerospace engine turbine blades (using precision investment casting).

#2. Forging – The “Heritage of Strength” Tempered Thousands of Times

Forging is a processing method where pressure (hammering or rolling) is applied to a heated metal blank to cause plastic deformation, thereby obtaining the desired shape and properties. The old saying “tempered a hundred times into steel” describes this process.

Basic Principle: Metal’s plasticity increases at high temperatures. External force compresses and elongates its internal grain structure, forming continuous grain flow (streamlines), which greatly enhances the material’s mechanical properties.

Main Classifications:

- Open-Die Forging: The metal is deformed between an upper and lower anvil. Tools are simple, but accuracy is low, mostly used for small batches or large blanks (e.g., large shafts, marine crankshafts).

- Closed-Die Forging: The metal is placed into a preset-shaped mold cavity and pressurized to fill it. High precision, high efficiency, suitable for mass production (e.g., automotive connecting rods, wrenches).

Main Advantages:

- Excellent Mechanical Properties: Forgings have higher strength, toughness, and fatigue resistance, making them the preferred choice for parts bearing heavy loads and impact loads.

- Complete Fiber Structure: Metal flow lines continuously distribute along the part’s contour, making it less prone to stress concentration.

Limitations:

- Difficult to manufacture overly complex-shaped parts.

- High equipment and mold costs, especially for closed-die forging.

- Relatively high material waste (flash).

Typical Applications: Automotive crankshafts, connecting rods, gear blanks, aerospace landing gear, wrenches, pliers, and other hand tools, as well as critical bolts and shaft parts.

#3. Stamping – The Efficient and Precise “Sheet Metal Tailor”

Stamping is a processing method that uses a mold to apply pressure to a metal sheet at room temperature, causing it to separate or plastically deform, thereby obtaining the desired part (stamping).

Basic Principle: Relies on a punch press (stamping press) to provide powerful, controllable force, enabling the rapid completion of cutting, bending, drawing, and other operations on thin sheet material in a mold.

Main Processes:

- Blanking: Separates the material, including punching out the part itself and creating holes in the part.

- Bending: Bends the sheet into a certain angle and shape.

- Drawing: Forms a flat blank into an open hollow part, like a cup or automotive fuel tank.

Main Advantages:

- Extremely High Production Efficiency: Can produce tens to hundreds of parts per minute, ideal for large-scale automated production.

- Excellent Consistency: Stable product quality, high dimensional accuracy, and strong interchangeability.High Material Utilization: Minimizes waste through precise nesting.

- Light Weight and Good Strength: Stamped parts can remain thin and light while achieving sufficient strength through structural design.

Limitations:

- Primarily suitable for thin sheet parts.

- Long mold manufacturing cycle and high cost, only suitable for mass production.

- Typical Applications: Automotive body panels (doors, hoods), beverage cans, smartphone metal frames, computer cases, coins, home appliance shells, etc.

#4. Welding – The “Material Suturing” That Integrates into One

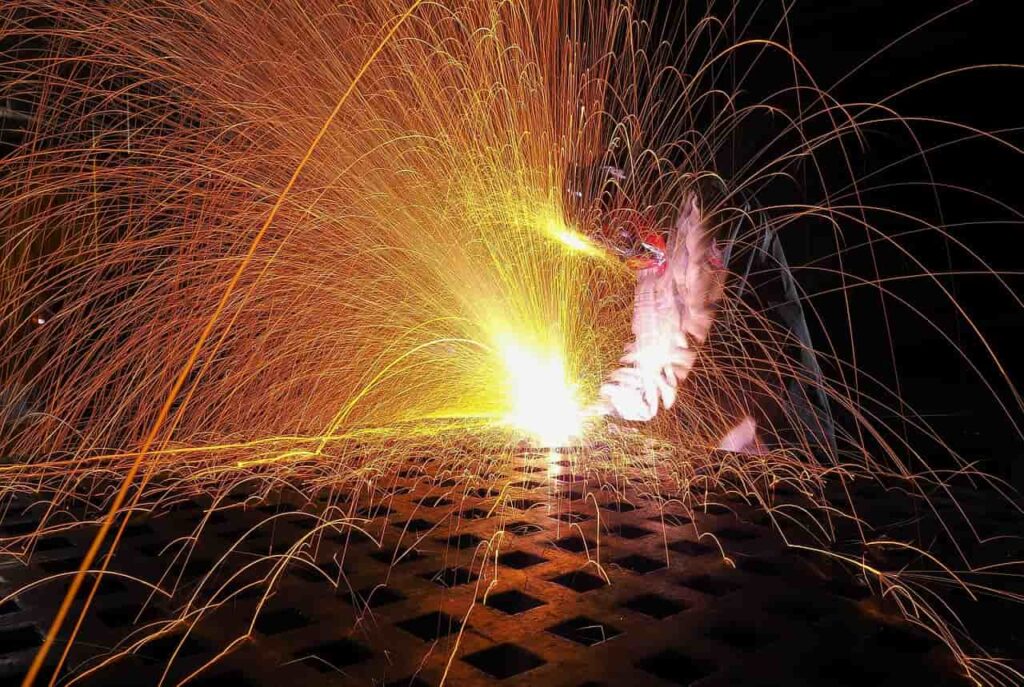

Welding is a process that uses heating, pressure, or both, to enable two separate metal workpieces to form a permanent connection at the atomic level. It “stitches” multiple parts into a single entity.

Basic Principle: Uses energy (electric arc, laser, friction heat, etc.) to melt the base materials at the joint, forming a molten pool that solidifies into a unified weld after cooling; or uses pressure to bring atoms at the contact surface sufficiently close to form metallic bonds.

Main Classifications:

- Fusion Welding: Heats the joint to a molten state; the most common method. Examples include arc welding (manual, TIG), laser welding, and electron beam welding.

- Pressure Welding: Achieves connection through plastic deformation under pressure. Examples include resistance spot welding and friction welding.

- Brazing: Uses a filler metal with a melting point lower than the base material. The liquid filler metal wets the base material, fills the joint gap, and diffuses with the base material to achieve connection (e.g., circuit board soldering).

Main Advantages:

- Achieves Permanent, Strong Connections: Joint strength can approach that of the base material itself.

- Builds Large from Small, Complex from Simple: Can weld simple castings, forgings, and profiles into complex large structures (e.g., bridges, ships).

- Good Sealing: Can be used to manufacture structures requiring sealing, like pressure vessels and pipelines.

Limitations:

- The microstructure and properties of the welded area (heat-affected zone) change, potentially causing deformation, stress, or cracks.

- Joint quality heavily relies on operator skill and process parameters.

- Not detachable.

Typical Applications: Ship hulls, building steel structures, bridges, pressure pipelines and vessels, automotive body assembly, aerospace fuselages.

#5. CNC Machining – The “Exquisite Carving” of Digital Control

CNC (Computer Numerical Control) machining is a subtractive manufacturing process. It uses pre-programmed computer instructions to control a machine tool in precisely cutting a solid blank, removing excess material to finally obtain a high-precision part.

Basic Principle: A 3D CAD model of the part is converted into a series of commands (G-code). The CNC system interprets these commands, driving the machine tool’s cutter to move along a preset path, performing milling, turning, drilling, and other operations on the blank fixed on the worktable.

Core Elements:

- Multi-Axis Linkage: Modern CNC machines can achieve 3-axis, 4-axis, or even 5-axis simultaneous movement, allowing for the machining of extremely complex curved geometries in a single setup.

- High Precision and Automation: The entire process is highly automated, requiring almost no manual intervention, and can stably achieve micron-level accuracy.

Main Advantages:

- Unparalleled Precision and Surface Quality: The ultimate method for manufacturing high-precision parts.

- High Flexibility and Versatility: Simply changing the program allows for machining different shaped parts, making it ideal for small-batch, high-variety production.Wide Range of Processable Materials: Including metals, plastics, composites, wood, etc.

- Capable of Manufacturing Extremely Complex Geometries: Especially 5-axis CNC, which is very powerful.

Limitations:

- Material Waste: Being a subtractive process, it generates a significant amount of chips.

- High Cost: Equipment and tools are expensive, and the machining time per part can be long.

- High Technical Barrier: Requires professional programmers and operators.

Typical Applications: Aerospace precision structural components, medical devices (e.g., artificial joints), automotive engine prototypes, smartphone molds, precision optical components, robot joints, etc.

Development History and Application Scope

# 1. Casting

Development History:

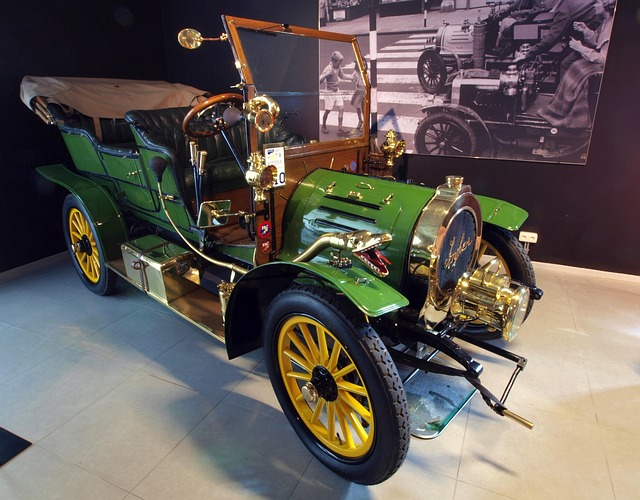

Ancient Times (circa 4000 BC): One of the earliest metal-forming processes mastered by humans, starting with the casting of simple copper tools (e.g., knives, axes), marking the beginning of the Bronze Age.

Feudal Era: The technology matured gradually. Bronze artifacts from China’s Shang and Zhou dynasties (e.g., the Simuwu Ding) represented the highest level of casting at the time. Later, iron casting developed for producing tools, weapons, and artworks (e.g., the Yongle Bell).

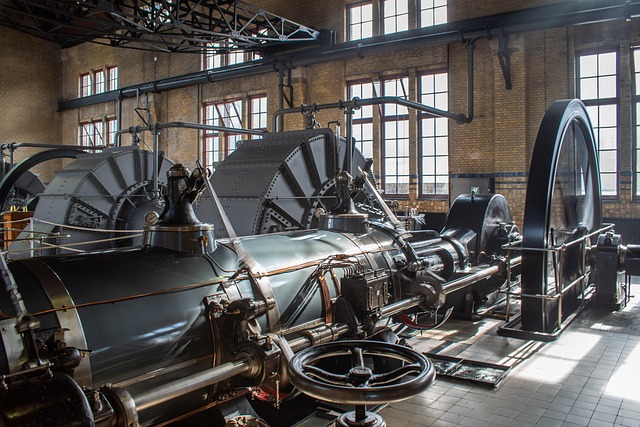

Industrial Revolution (Late 18th Century): Casting became the cornerstone of modern industry. The cylinders of steam engines required large, complex cast iron parts, greatly promoting the scaling and development of sand casting.

20th Century to Present: More precision casting methods emerged, such as die casting (for zinc, aluminum, and magnesium alloys), investment casting (for complex aerospace parts), and centrifugal casting. The casting process also became mechanized, automated, and optimized through computer simulations.

Application Scope:

Core Feature: Manufacturing blanks and parts with complex shapes, especially those with intricate internal cavities.

Traditional Fields: Artworks, statues, bells, water pipes, municipal manhole covers.

Modern Industry:

Automotive Industry: Engine blocks, cylinder heads, transmission housings, hubs.

Aerospace: Engine turbine blades, casings, structural components.

Machine Tool Industry: Large foundational components like beds, columns, and guides.

Power Industry: Large rotors and stators for hydraulic turbines, steam turbines, and generators.

# 2. Forging

Development History:

Ancient Times: Initially involved manual hammering by artisans, later aided by water-powered hammers, to process heated metal into stronger tools and weapons. The phrase “repeatedly tempered into steel” vividly describes ancient forging techniques.

Industrial Revolution: The invention of the steam hammer enabled the forging of large workpieces, such as crankshafts and connecting rods for steam engines.

Mid-19th Century: The invention of forging presses provided more stable and controllable pressure methods.

20th Century: Die forging was widely adopted in the automotive and aviation industries. New processes like closed-die forging (flashless forging) improved material utilization.

Modern Era: Advanced technologies such as isothermal forging and superplastic forming emerged, used for manufacturing high-performance titanium alloys and superalloy aerospace parts.

Application Scope:

Core Feature: Manufacturing critical parts that withstand high loads, high impact, and require exceptional strength and reliability.

Traditional Fields: Swords, armor, hand tools (hammers, pliers, wrenches).

Modern Industry:

Automotive Industry: Crankshafts, connecting rods, camshafts, gears, front axles.

Aerospace: Aircraft landing gear, turbine disks, compressor disks, engine shafts, critical structural components.

Heavy Machinery: Large generator main shafts, marine crankshafts, rollers, high-pressure vessels.

General Machinery: High-strength bolts, nuts.

# 3. Stamping

Development History:

Ancient Times: Its earliest form was the stamping of coins.

Late Industrial Revolution (19th Century): Simple blanking and bending molds began to appear as demand for thin sheet metal parts increased for products like printing presses and sewing machines.

Early 20th Century: The rise of the automotive industry was the biggest driver of stamping technology. The Ford Model T was the first to mass-produce body panels using stamping, achieving high-efficiency, low-cost mass production.

Mid-20th Century to Present: Automated stamping production lines, progressive dies, and multi-station die technology advanced rapidly, achieving efficiencies of dozens of parts per minute. Computer-aided design (CAD/CAE) technologies made mold design and manufacturing more precise and efficient.

Application Scope:

Core Feature: High-efficiency, mass production of thin-walled metal sheet parts.

Traditional Fields: Cutlery, kitchenware, stationery (paper clips, staples), coins.

Modern Industry:

Automotive Industry: The primary application field, including body panels (doors, hoods, fenders) and structural parts (chassis, frames).

Home Appliance Industry: Casings and internal structural parts for refrigerators, washing machines, and air conditioners.

Electronics Industry: Smartphone frames, computer cases, connectors, shielding covers.

Daily Hardware: Beverage cans, metal packaging, lamp housings.

# 4. Welding

Development History:

Ancient Times: Forge welding was the earliest form, such as hammering two pieces of heated iron together on an anvil.

Late 19th Century: The discovery of the electric arc revolutionized welding technology, leading to carbon arc welding and metal arc welding.

First Half of the 20th Century: To meet wartime demands for shipbuilding and aircraft manufacturing, welding technology advanced rapidly. Efficient, high-quality methods like submerged arc welding, tungsten inert gas (TIG) welding, and metal inert gas/metal active gas (MIG/MAG) welding emerged.

Late 20th Century to Present: Advanced welding technologies such as laser welding, electron beam welding, friction welding, and friction stir welding were developed, enabling the welding of refractory metals, dissimilar materials, and applications in high-precision fields. Robotic automated welding has become mainstream in modern production lines.

Application Scope:

Core Feature: Achieving permanent joining of metal materials for constructing large, complex, or sealed structures.

Traditional Fields: Iron crafts, jewelry.

Modern Industry:

Construction: Steel structures for skyscrapers, stadiums, and bridges.

Shipbuilding and Offshore Engineering: Ship hulls, offshore platforms.

Pressure Vessels: Boilers, storage tanks, chemical pipelines.

Automotive Industry: Body assembly (spot welding), frames (arc welding).

Aerospace: Rocket fuel tanks, aircraft fuselages.

Microelectronics: Chip wire bonding (micro soldering).

# 5. CNC Machining

Development History:

1940s-1950s: Its predecessor was numerical control (NC) technology, initially developed to meet the machining needs of complex curved parts (e.g., helicopter propellers) in the aerospace industry, using punched tape for programming.

1970s: The invention of microprocessors gave rise to computer numerical control (CNC), making programming and operation more flexible and powerful.

1980s-1990s: The integration of CAD/CAM (computer-aided design/manufacturing) software with CNC technology greatly simplified the process from design to production. Multi-axis machining centers became widespread.

21st Century to Present: Trends include high speed, high precision, intelligence, and composability. Five-axis machining has become the standard for manufacturing complex parts. Integration with industrial robots and automated measurement systems has formed flexible manufacturing cells (FMC) and flexible manufacturing systems (FMS).

Application Scope:

Core Feature: Manufacturing parts with high precision, high complexity, and stringent requirements for dimensional accuracy and surface quality.

Prototype Manufacturing: Functional prototypes in product development.

Mold Manufacturing: Precision machining of cavities for injection molds, stamping dies, and die-casting molds.

Aerospace: Aircraft structural components, engine casings, blisks, navigation equipment parts.

Medical Devices: Artificial joints (hips, knees), surgical robot components, dental implants.

Automotive Industry: Engine prototypes, high-precision transmission gears, customized performance parts.

Precision Instruments/Optics: Optical mounts, mirrors, precision transmission components.

Summary

These five processes support modern manufacturing from different dimensions:

Casting and forging provide the basic blank forms and intrinsic properties.

Stamping defines the mass production of sheet metal parts with unparalleled efficiency.

Welding is the “suturing technique” that joins various parts into the final integrated structure.

CNC machining is the “refinement and carving” that achieves final precision and complexity.

They complement each other, forming a complete manufacturing chain from raw materials to complex finished products, and are indispensable cornerstones of industrial civilization.

These five processes are not mutually exclusive but complementary. The production of a car perfectly integrates all five: the cast engine block, forged crankshaft and connecting rods, stamped body panels, the body-in-white welded together, and high-precision engine injection systems and molds manufactured by CNC machining. It is these ancient yet vibrant manufacturing crafts that collectively shape the material world we see today.