CNC Machining vs. 3D Printing: The Ultimate Guide to Choosing the Right Manufacturing Process

In the world of modern manufacturing, two technologies dominate the conversation: CNC machining and 3D printing. Both are revolutionary, both can create complex parts, and both have become essential tools for engineers, designers, and hobbyists. But despite their overlapping capabilities, they are fundamentally different beasts. Choosing the wrong one can lead to wasted time, ballooning costs, and a part that simply doesn’t perform.

So, how do you decide? Is it a simple case of “old school” vs. “new school”? Not at all. The choice hinges on a clear understanding of your project’s specific requirements. This guide will demystify these two powerhouse technologies, breaking down their differences and providing a clear framework for when to choose CNC machining and when to harness the power of 3D printing.

Part 1: The Core Difference – Subtractive vs. Additive

To understand their applications, you must first grasp their fundamental principles.

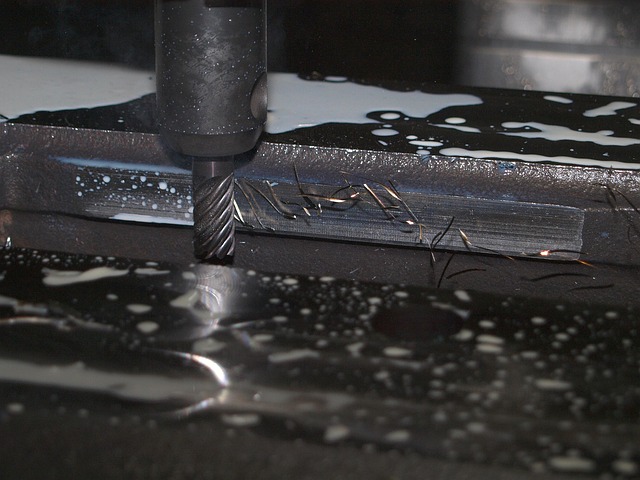

CNC Machining: The Art of Subtraction

CNC (Computer Numerical Control) machining is a subtractive process. It starts with a solid block of material (called a blank or workpiece)—such as metal, plastic, or wood—and uses a variety of sharp, rotating cutting tools to systematically remove material. A computer-controlled program guides the tools along precise paths, carving away everything that isn’t the final part. Think of it as a highly sophisticated, automated sculptor chiseling away at a block of marble.

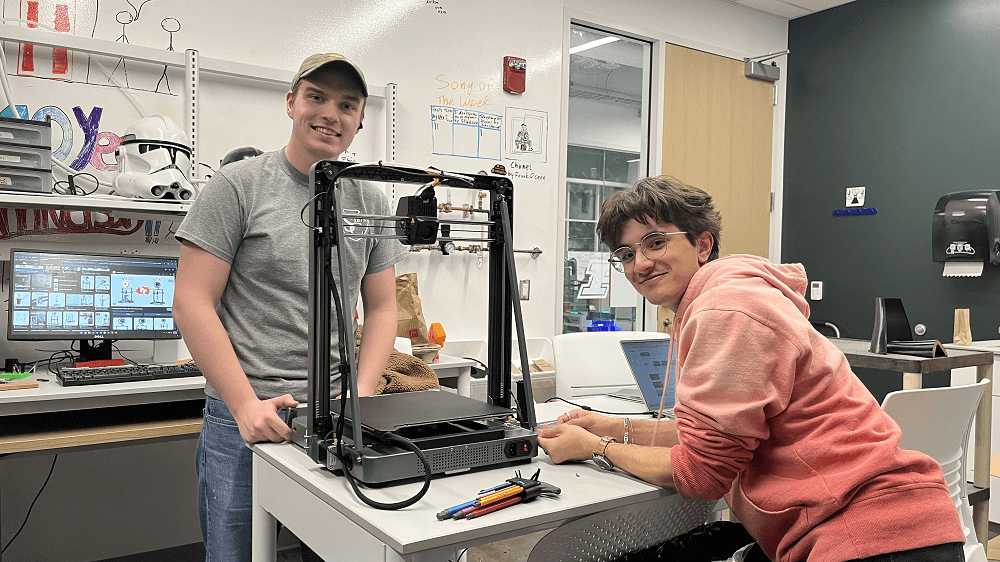

3D Printing: The Science of Addition

3D Printing, also known as Additive Manufacturing (AM), is the polar opposite. Instead of cutting away, it builds a part layer by layer from the bottom up. It starts with nothing and adds material only where it’s needed, based on a digital 3D model (an STL or OBJ file). The material—which can be plastic resin, metal powder, or even concrete—is fused together using a heat source (like a laser or extruder) until the entire object is formed.

This core difference—subtractive vs. additive—is the root of every subsequent advantage and limitation.

Part 2: A Detailed Head-to-Head Comparison

Let’s break down the key factors that influence the decision-making process.

| Feature | CNC Machining | 3D Printing |

| Process | Subtractive | Additive |

| Materials | Wide range of engineering-grade materials. Metals (Aluminum, Stainless Steel, Titanium, Brass), Plastics (ABS, Nylon, Polycarbonate, PEEK), Wood, and Composites. | Growing but more limited range. Primarily plastics (PLA, ABS, Resins, Nylon) and specialized metal powders. Materials are often proprietary to the printer manufacturer. |

| Material Strength | Excellent and isotropic. The parts are carved from solid blocks, meaning they are fully dense and have consistent strength in all directions, making them ideal for functional, load-bearing components. | Can be anisotropic. Strength can be weaker between layers (the Z-axis). While post-processing can help, 3D-printed parts may delaminate under specific stress. However, technologies like SLS and metal SLM produce very strong parts. |

| Accuracy & Surface Finish | High precision and excellent surface finish. CNC machines can achieve extremely tight tolerances (often within ±0.025 mm or better). The surface straight off the machine is typically smooth, often only requiring minor finishing. | Good precision, but typically layered surface. Tolerances are good (around ±0.1 mm to ±0.5 mm) but generally not as tight as CNC. The “stair-stepping” effect from layers is often visible and may require sanding or vapor smoothing for a smooth finish. |

| Design Complexity & Geometry | Limited by tool access. The cutting tool must physically reach all surfaces to be machined. This makes internal geometries, undercuts, and truly complex, organic shapes challenging and sometimes impossible without designing the part in multiple assemblies. | Unparalleled geometric freedom. Complexity is (almost) free. 3D printing excels at creating intricate lattices, internal channels, hollow structures, and highly complex organic shapes (like custom medical implants) that are impossible to machine in a single piece. |

| Speed & Lead Time | Setup can be slow, but production is fast. Creating the toolpaths (CAM programming) and fixturing the material can be time-consuming. However, once set up, machining a single part is relatively quick. Ideal for low-to-medium volume production. | Very fast prototyping, slower for volume. There is virtually no setup time; you just load the file and print. This makes it incredibly fast for a first prototype. However, the layer-by-layer process is inherently slower for producing multiple copies, as each part adds to the total print time. |

| Cost Structure | High initial cost, lower per-part cost at volume. Cost is driven by machine time, material cost, and operator skill. For large production runs, the cost per part becomes very efficient. Material waste (chips/swarf) can be a cost factor. | Low initial cost, higher per-part cost. Cost is driven by the volume of material used and print time. There is little to no waste (unused powder can often be recycled). Excellent for one-off parts and prototypes, but economies of scale are less dramatic. |

Part 3: When to Choose CNC Machining

Choose CNC machining when your priority is:

1. Strength and Performance: If you need a part that will endure high stress, heat, or harsh environmental conditions, CNC is the default choice. The use of solid, durable materials like aluminum or steel with isotropic properties is unbeatable for functional end-use parts.

* Examples: Engine brackets, drone arms, gears, hydraulic components, and high-stress mechanical assemblies.

2. Tight Tolerances and Smooth Finishes: When a part must fit with other components with precision, CNC’s accuracy is critical. If you need a smooth, functional surface right out of the machine, CNC delivers.

* Examples: Surgical instrument components, mating parts for machinery, and injection molds.

3. Volume Production of Simple Parts: While 3D printing is improving for production (a field called Additive Manufacturing), CNC is often more cost-effective for producing hundreds or thousands of relatively simple, robust parts. The speed of milling once the setup is complete is hard to beat.

4. Working with Specific, High-Performance Materials: If your design requires a specific engineering-grade plastic (like PEEK or UHMW) or a wide variety of metals, CNC offers a much broader and often more affordable material selection.

Part 4: When to Choose 3D Printing

Choose 3D printing when your priority is:

1. Rapid Prototyping and Iteration: This is 3D printing’s sweet spot. The ability to go from a digital model to a physical part in hours, with zero tooling, is transformative for the design process. You can test form, fit, and function incredibly quickly and make revisions on the fly.

* Examples: Concept models, functional prototypes for design validation, and ergonomic testing.

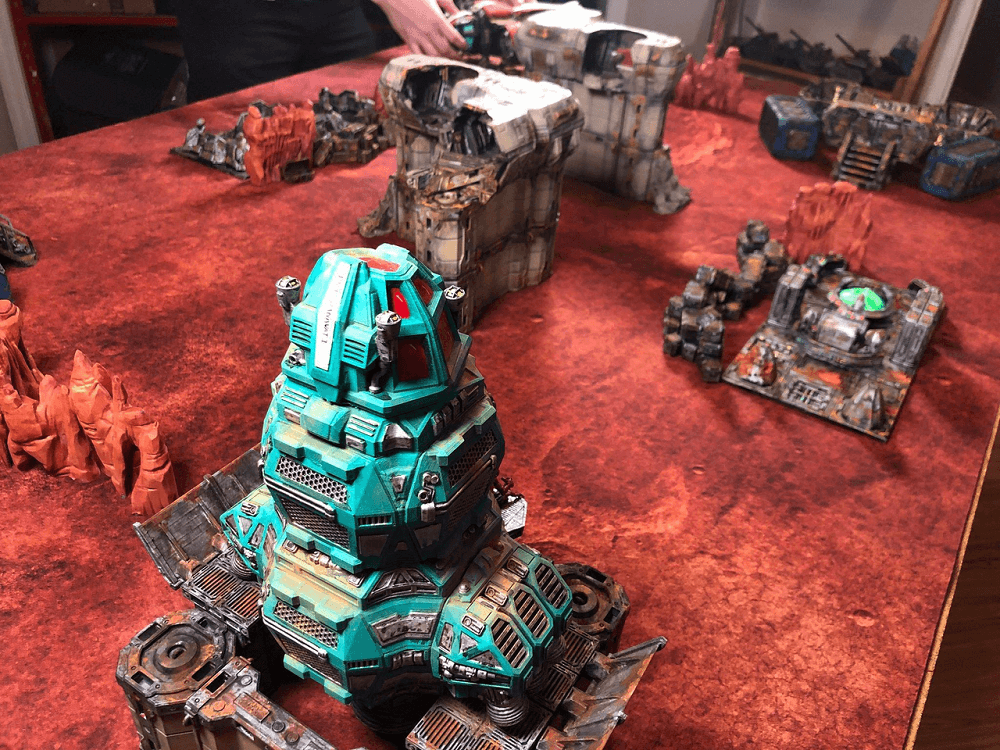

2. Extreme Design Complexity: If your part features intricate details, internal channels, or organic, lattice-like structures inspired by nature (biomimicry), 3D printing is the only practical choice.

* Examples: Custom lightweight aerospace brackets, fluid flow optimization manifolds with internal cooling channels, and personalized medical implants and surgical guides.

3. Customization and On-Demand Manufacturing: 3D printing is ideal for producing one-off, customized items without the need for expensive molds or tooling. This makes it perfect for medical, dental, and consumer goods applications.

* Examples: Hearing aids, dental aligners, custom-fit prosthetic limbs, and personalized consumer products.

4. Cost-Effective Low-Volume Production: For producing a small batch of parts (1-10 units), 3D printing is almost always more economical than CNC because it avoids the high setup costs. This is ideal for niche products, bridge production, or crowdfunding campaigns.

5. Assembly Consolidation: A powerful use of 3D printing is to combine what would be multiple CNC-machined parts assembled together into a single, printed unit. This reduces assembly time, potential failure points, and often weight.

* Example: Printing a hinge and its housing as one single piece instead of machining and assembling 5 separate components.

Part 5: The Decision Flowchart

Ask yourself these questions:

1. What is the primary purpose of the part?

* Strong, functional, end-use part -> Lean towards CNC.

* Prototype, model, or complex/low-volume part -> Lean towards 3D Printing.

2. How complex is the geometry?

* Relatively simple with standard features -> CNC can handle it efficiently.

* Highly complex with internal features/lattices -> 3D Printing is the clear winner.

3. What material is required?

* Standard engineering metal or high-performance plastic -> CNC.

* Standard plastic resin or specialized metal powder is acceptable -> 3D Printing.

4. What is the required quantity?

* High volume (100s+) -> CNC typically has a better cost curve.

* Low volume (1-50) -> 3D Printing is often faster and cheaper.

5. What are the tolerance and finish requirements?

* Extremely tight tolerances and a smooth finish are critical -> CNC.

* Good enough tolerances are acceptable; finish can be secondary -> 3D Printing.

Conclusion: Not Competitors, but Allies

The takeaway is not that one technology is better than the other. Instead, CNC machining and 3D printing are complementary tools in a modern manufacturer’s toolbox. The most successful engineers and designers understand the strengths of each and select the tool that best fits the job.

Often, the two technologies are used in tandem throughout a product’s lifecycle: 3D printing is used for rapid prototyping and initial design validation, while CNC machining is employed for creating the final, high-performance production parts or the tooling needed for mass production.

By moving beyond the hype and understanding the practical differences, you can make informed decisions that save time, reduce costs, and ultimately lead to a better product.