A Guide to the Main Metal Processing Processes

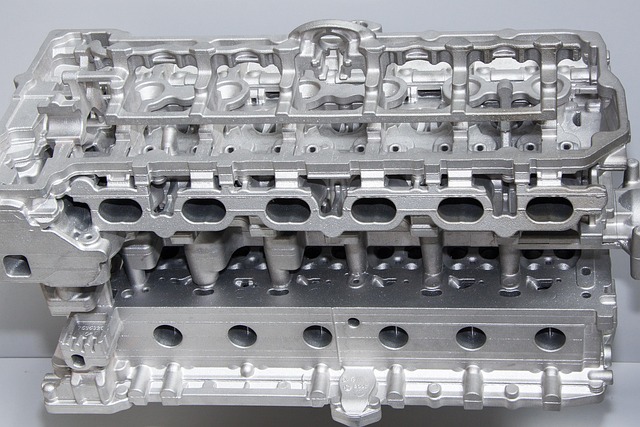

Metal processing is the process of shaping metal materials into parts or products with the desired form, dimensions, and properties through a series of technical means. It is the cornerstone of modern manufacturing. From grand aerospace engines to precision medical implants, all rely on various metal processing techniques. These processes can be broadly divided into three main categories: Subtractive Manufacturing, Additive Manufacturing, and Forming Manufacturing.

I. Subtractive Manufacturing

As the name suggests, subtractive manufacturing is a process that achieves the desired shape by removing material. It is like a sculptor carving a block of marble, chipping away unwanted parts. This is the most traditional and widely used processing method.

- Traditional Machining

- Turning: The workpiece rotates, and the cutting tool moves linearly. Primarily used for machining rotational parts like cylinders and cones, such as shafts, rods, and sleeves. The machine tool used for turning is called a Lathe.

- Milling: The cutting tool rotates, and the workpiece is fixed or moves. Using multi-edge milling cutters, various features can be machined, including planes, grooves, gears, and complex 3D surfaces. The machine tool used for milling is called a Milling Machine.

- Drilling: Uses a rotating drill bit to create round holes in solid material.

- Grinding: Uses a high-speed rotating grinding wheel for precision finishing of a workpiece’s surface, achieving extremely high dimensional accuracy and excellent surface finish.

- Planing & Shaping: Mainly used for machining large workpiece planes, but with low efficiency; now largely replaced by milling.

- CNC Machining

This is the modern upgrade of traditional machining. Computer Numerical Control (CNC) technology controls machine tool movements through pre-programmed code instructions, enabling automated, high-precision, and highly complex machining.- CNC Lathes, CNC Milling Machines, and CNC Machining Centers are indispensable equipment in modern mold making, aerospace, precision instruments, and other fields.

- Non-Traditional Machining (Special Machining)

Used for machining special materials or structures with high hardness, high toughness, or complex micro-features.- EDM (Electrical Discharge Machining): Uses instantaneous high temperatures generated by spark discharges to erode metal material, commonly known as “spark machining.” Particularly suitable for machining hard alloys and complex mold cavities.

- Wire Cut EDM: A type of EDM that uses a moving metal wire as an electrode, mainly used for precision cutting of 2D contours.

- Laser Cutting: Uses a high-energy-density laser beam to irradiate the workpiece, causing it to rapidly melt and vaporize, achieving cutting. It is fast, precise, and applicable to a wide range of materials.

- Water Jet Cutting: Uses an ultra-high-pressure water stream (often mixed with abrasive) to impact the material for cutting. It is a cold cutting process with no heat-affected zone, making it suitable for temperature-sensitive materials.

II. Forming Manufacturing

Forming manufacturing is a process that uses external force to cause plastic deformation of metal material in a solid or semi-liquid state to obtain the desired shape. Its advantages include high material utilization, high production efficiency, and the ability to improve the mechanical properties of the material.

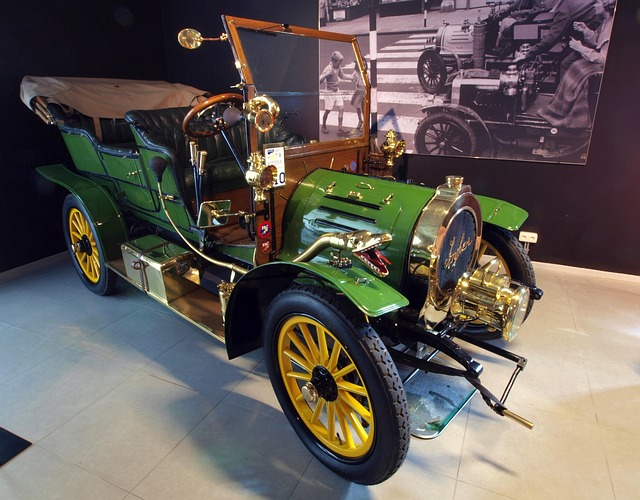

- Casting

Molten metal is poured into a pre-made mold cavity and allowed to cool and solidify into a part. Suitable for manufacturing blanks with complex shapes, especially those with intricate internal cavities.- Common processes: Sand Casting, Die Casting, Investment Casting.

- Plastic Forming

- Forging: On forging equipment, a heated metal blank is plastically deformed through hammering or pressure. It significantly refines grains and improves the strength and toughness of the part. Blanks for critical components like engine crankshafts and connecting rods are often forged.

- Stamping: Typically performed at room temperature, pressure is applied to a sheet metal blank using a die to separate or plastically deform it, obtaining a stamped part. Widely used for car bodies, appliance housings, daily necessities, etc.

- Rolling: A metal billet passes through the gap of a pair of rotating rolls, reducing its cross-section and increasing its length due to compression. The primary method for producing profiles, plates, and tubes.

- Extrusion: A metal billet is placed in a sealed extrusion chamber, pressure is applied at one end, forcing it to exit through a die of a specific shape. Used for producing long, straight profiles and tubes.

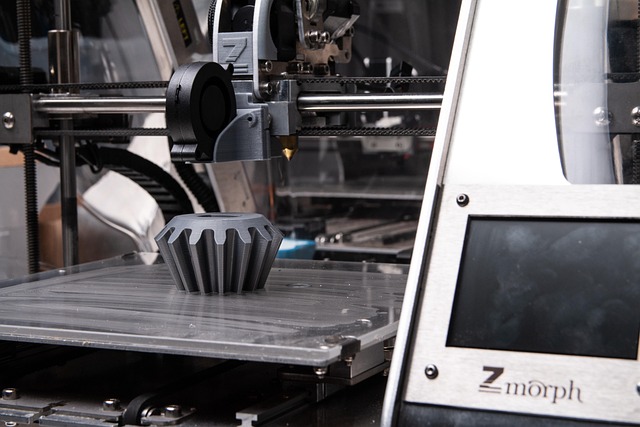

III. Additive Manufacturing – 3D Printing

Additive manufacturing is a revolutionary technology in recent years that constructs three-dimensional objects by layering materials, completely opposite to the philosophy of subtractive manufacturing.

- SLM (Selective Laser Melting) / DMLS (Direct Metal Laser Sintering): Uses a high-energy laser beam to selectively melt layers of metal powder based on 3D model data, building up layers to form dense metal parts. It can directly manufacture complex structures difficult for traditional methods (like internal conformal cooling channels), integrated structures, and lightweight structures. Widely used in aerospace, medical implants, and high-end mold fields.

IV. Joining and Other Processing Techniques

- Joining Processes

- Welding: Forms a permanent joint by heating or pressurizing to fuse atoms between metal parts. Common types include arc welding, TIG/MIG welding, laser welding, etc.

- Riveting, Bolting: Mechanical joining methods, can be disassembled.

- Heat Treatment

Although not a shape-changing process, it is a crucial part of metal processing. By strictly controlling heating, holding, and cooling processes, it can significantly alter the internal microstructure of the metal, thereby obtaining desired properties such as hardness, strength, toughness, and wear resistance. Common processes include: Annealing, Normalizing, Quenching, Tempering. - Surface Treatment

Used to enhance part surface properties or appearance, such as:- Electroplating: Chrome plating, zinc plating, etc., for corrosion resistance, wear resistance, and decoration.

- Spraying: Spray painting, powder coating.

- Anodizing: Mainly used for aluminum materials, forming a wear-resistant and corrosion-resistant oxide layer.

Summary

Metal processing technology is a vast and precise system. In actual production, multiple processes often need to be combined. For example, a part might first be made into a blank by casting or forging, then machined to precise dimensions by turning, milling, etc., followed by heat treatment to improve properties, and finally surface treatment. Choosing the right processing route is key to optimizing cost, efficiency, and performance in manufacturing.