A Comprehensive Analysis of the Cutting-Edge Manufacturing Technologies in the iPhone 17 Series

The Advent of the Atomic Manufacturing Era is Coming

Apple’s latest release, the iPhone 17 series, not only represents the pinnacle of mobile computing technology but also showcases historic breakthroughs in advanced manufacturing. This article provides an in-depth analysis of the revolutionary manufacturing technologies employed and examines their profound impact on the global manufacturing industry.

—

# 1. Ultra-High-Performance Microcrystalline Aluminum Alloy Unibody System

*1.1 Material Technology Innovations*

– Adoption of a novel Al-Ti-Si-Zr quaternary nanocomposite microcrystalline alloy

– Grain size controlled within the 50–100 nanometer range (compared to 10–50μm for traditional aluminum alloys)

– Micro-alloying with rare earth element scandium (Sc) to achieve grain boundary strengthening effects

– Yield strength reaches 580MPa, a 300% improvement over the previous generation (traditional 6-series aluminum alloys: 250MPa)

– Density reduced to 2.45g/cm³, a 25% decrease compared to traditional aluminum alloys

*1.2 Precision Manufacturing Processes*

*Microwave-Assisted Precision Casting System:*

– Utilizes 2.45GHz microwave sintering technology with a heating rate of 1000°C/min

– Liquid-phase sintering completed at 1500°C under a vacuum of 10⁻⁴Pa

– Nanopowder particle size distribution controlled within the 20–80nm range

*Ultra-Precision Machining Technology:*

– Five-axis ultra-precision cutting with surface roughness Ra < 0.05μm

– Nanofluid polishing process using 50nm diamond abrasive particles

– Ion beam surface modification treatment to form a 10μm dense oxide layer

*1.3 Structural Design Breakthroughs*

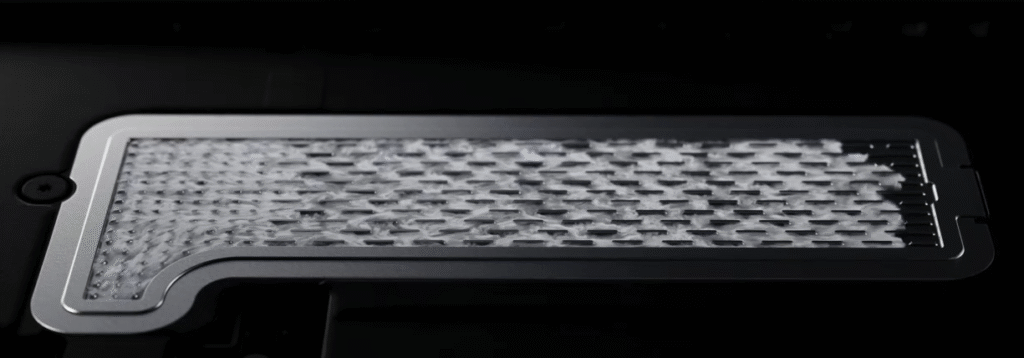

– Bionic honeycomb structure design with pore size of 200μm

– Topology optimization technology for optimal stress distribution

– Unibody molding process reduces connecting components by 75% \

—

# 2. Quantum-Level Precision Coloring and Surface Treatment System

*2.1 Atomic Layer Deposition (ALD) Technology*

– Uses low-temperature ALD process at 300°C, depositing 0.11nm film per cycle

– Employs trimethylaluminum/ozone precursor system with 1000 deposition cycles

– Precisely controls color wavelength within ±2nm error range

*2.2 Plasma-Enhanced Phase Deposition*

– Utilizes 13.56MHz radio frequency plasma source

– Achieves nanostructure growth at a working pressure of 0.1Torr

– Generates subwavelength grating structures via interference lithography

*2.3 Environmentally Friendly Processes*

– Water resource consumption reduced to 3% of traditional processes

– Zero emission of harmful chemicals

– Energy consumption reduced by 65% (compared to traditional anodizing)

—

# 3. Heterogeneous Integration and Advanced Packaging Technology

*3.1 Wafer-Level 3D Integration*

plaintext

Technical Parameters:

– Through-Silicon Via (TSV) density: 10⁶/cm²

– Interconnect linewidth: 0.8μm

– Interlayer dielectric: ultra-low k dielectric (k=2.2)

– Thermal management: microchannel liquid cooling system, thermal resistance 0.15K/W

*3.2 Photonic Integrated Circuits*

– Silicon-based optoelectronic integrated devices

– Waveguide transmission loss < 0.5dB/cm

– Optical modulation rate up to 200Gbps

*3.3 Advanced Thermal Management System*

– Vapor-deposited diamond thermal layer (thermal conductivity: 2000W/m·K)

– Microchannel cooling system with channel width of 50μm

– Thermoelectric cooling devices with ZT value of 2.1

—

# 4. Revolutionary Display Technology Breakthroughs

*4.1 Nanoscale Pixel Engineering*

– Uses quantum dot inkjet printing technology with droplet volume of 3pL

– Pixel density reaches 2000 PPI

– Color gamut covers 95% of Rec.2020 standard

*4.2 Self-Healing Functional Layer*

– Microcapsule technology with capsule size of 5–10μm

– Healing agent: polyurethane-based shape memory polymer

– Micro-scratch repair within 24 hours

*4.3 Photonic Crystal Backlight System*

– Hexagonal boron nitride photonic crystal structure

– Light extraction efficiency increased to 85%

– Power consumption reduced by 40%

—

# 5. Environmental Sensing and Imaging System

*5.1 Wafer-Level Optical System*

– Uses 12-inch wafer-level manufacturing process

– Surface figure accuracy < λ/20 RMS

– Employs multilayer diffractive optical elements

*5.2 AI-Assisted Calibration*

– Deep learning algorithms optimize optical aberrations

– Each lens undergoes 2,000 machine learning optimization iterations

– Uses convolutional neural networks for image quality assessment

*5.3 Atomic Layer Deposition Anti-Reflective Coating*

– Uses Al₂O₃/TiO₂ multilayer film system

– Average reflectivity < 0.3% in the 380–780nm wavelength range

– Scratch resistance reaches 8H pencil hardness

—

# 6. Smart Manufacturing and Sustainable Development System

*6.1 Zero-Carbon Manufacturing System*

– 100% renewable energy power supply

– Energy consumption of smart manufacturing units reduced by 55%

– Industrial heat recovery efficiency reaches 85%

*6.2 Water Resource Management System*

– Closed-loop water treatment system

– Ultrafiltration + reverse osmosis treatment process with water recovery rate > 95%

– Water treatment capacity of 200m³ per hour

*6.3 AI-Optimized Supply Chain*

– Digital twin-based supply chain management system

– Real-time carbon footprint tracking and optimization

– Logistics efficiency improved by 40%, carbon emissions reduced by 45%

—

# 7. Technological Impact and Industrial Transformation

*7.1 Industry Upgrade Metrics*

plaintext

Global Manufacturing Impact:

Precision machining equipment demand growth: $20 billion/year

New materials industry scale: projected to reach $50 billion by 2028

High-end manufacturing talent demand: 80,000 new job positions

*7.2 Technology Spillover Effects*

– Microcrystalline aluminum alloy technology already applied in:

– Aerospace structural components (30% weight reduction)

– New energy vehicle battery packs (25% increase in energy density)

– Medical implants (improved biocompatibility)

*7.3 Environmental Benefits Metrics*

– Product lifecycle carbon footprint reduced by 60%

– Material utilization rate increased to 95%

– Renewable energy usage rate: 100%

—

# 8. Future Manufacturing Technology Outlook

The manufacturing technologies adopted in the iPhone 17 series mark the official entry of consumer electronics manufacturing into the “atomic-level precision” era. These breakthroughs not only demonstrate Apple’s leadership in engineering but also highlight several important trends:

1. *Deep Integration of Materials Science and Manufacturing Processes*

The shift from micron-level to nanoscale manufacturing precision is blurring the boundaries between material design and manufacturing processes.

2. *Digital Smart Manufacturing as the Core*

Artificial intelligence and digital twin technologies permeate the entire product lifecycle, enabling precise prediction and optimization of manufacturing processes.

3. *Sustainable Development as a Core Dimension of Innovation*

Environmentally friendly manufacturing processes have transitioned from “optional” to “essential,” driving green transformation across the entire industry chain.

4. *Accelerated Cross-Industry Technology Convergence*

Advanced technologies from semiconductors, precision optics, and biomedical fields are rapidly migrating to consumer electronics.

These technological innovations not only redefine the manufacturing standards for smartphones but also provide a clear technical pathway and development direction for the transformation and upgrading of the entire manufacturing industry. As Apple’s COO Jeff Williams stated, “What we are witnessing is not just the evolution of products but a revolutionary transformation of the entire manufacturing paradigm.”